|

Arado Ar 234B Cockpit

Cutting Edge Modelworks

S

u m m a r y

|

| Catalogue Number

and Description: |

CEC48406 Arado Ar 234B Super

Detailed Cockpit for Hasegawa. |

| Scale: |

1/48 |

| Contents and Media: |

20 parts in grey resin (including a few spare

levers/handles) |

| Price: |

USD$11.99 from Meteor

Productions website |

| Review Type: |

FirstLook and

Construction |

| Advantages: |

Accurate and complete; only replaces what needs

replacing; will be very visible behind the clear nose of the Ar

234; crisp details; perfect casting; minimal cleanup required; good

instructions |

| Disadvantages: |

|

| Recommendation: |

Highly Recommended |

Reviewed by Brett Green

HyperScale is proudly sponsored by Meteor

Productions

Hasegawa's new 1/48 scale Arado Ar 234B is an excellent

kit.

The cockpit is a crucial area of this model, because the

large clear nose will reveal all the detail inside. Fortunately, Hasegawa

has done a nice job with this aspect of the kit and many modellers will be

perfectly happy with he cockpit straight from the box. However, the

limitations of injection moulding technology, and some missing parts from

the research subject at the National Air and Space Museum, means that

there is room for improvement and addition.

Cutting Edge has released a cockpit update set for the

Hasegawa 1/48 scale Arado Ar 234. This resin set acknowledges that most of

the cockpit is very good already, and therefore concentrates only on the

areas that need improvement.

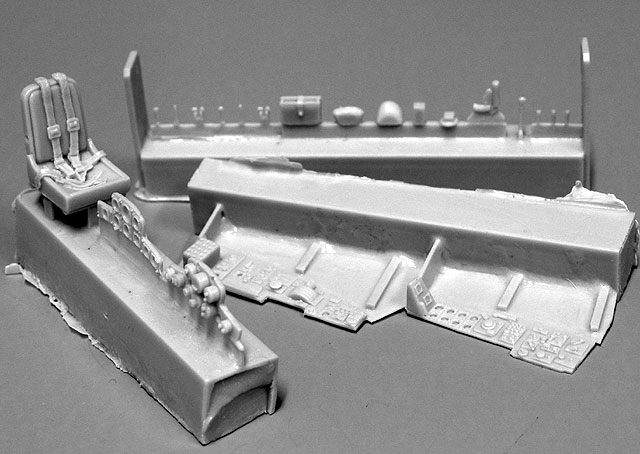

20 parts in grey resin are supplied on three casting

blocks. The parts can be easily removed with a sharp knife, but I found

that my side cutters were helpful in nibbling away the block from

underneath the replacement seat.

The resin parts on my sample are free of any

imperfections, and casting is up to the usual high Cutting Edge standard.

A small acetate sheet with printed instruments is also provided.

The highlights of the set are the seat with its cast-on

backrest and harness, the crisply detailed side consoles and a two-piece

panel with raised instrument housings on the back. The batch of small

details will add an authentically busy atmosphere to the cockpit and, even

better, it will all be visible through the clear nose.

Instructions are also good. Ten drawings and photographs

accompany the instruction text, but there are no real traps to assembling

this simple detail set. The instructions do suggest the addition of

"wiring" behind the instrument panel from stretched sprue or fusewire, as

this area is very exposed to view.

I have been looking for an excuse to start my Hasegawa

Arado Ar 234, and the arrival of the Cutting Edge cockpit was the trigger.

Preparing the Kit Parts

First, the kit parts were prepared. The basic kit cockpit

tub is retained, but the raised detail on the side consoles must be

removed. I scraped the higher features off with a sharp hobby knife, then

sanded off the remainder with a coarse sanding stick.

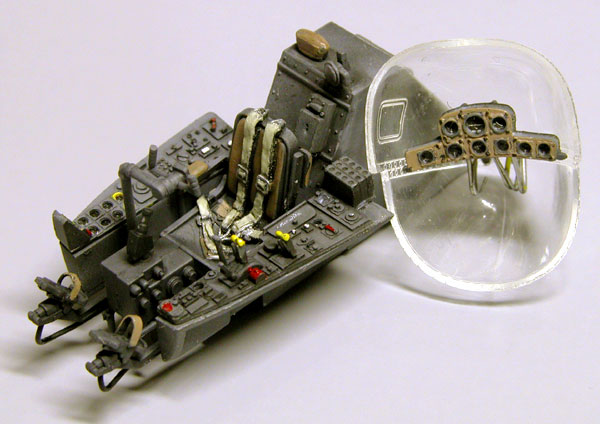

The clear nose part (Hasegawa part no. P1) has a slight

step and moulding seam running from top to bottom along the centreline. I

started by scraping the seam line with the blade of a hobby knife until

the step was eliminated. Next, I sanded the now-cloudy band down the

centre of the nose with progressively finer grit sanding sticks. When the

visible scratches were hidden, I applied a generous coat of Gunze Mr

Polishing Compound (although toothpaste does a good job too), waited for

it to dry, then polished the compound off the clear plastic. After a final

buffing with a sanding stick, the seam line was officially gone!

It is important to further prepare the clear kit parts

with a thorough soaking bath in Future floor polish. This will vaccinate

the canopy from fogging when resin parts are glued to the plastic. It will

also bestow a sparkling shine to the canopy.

Assembly and Detailing

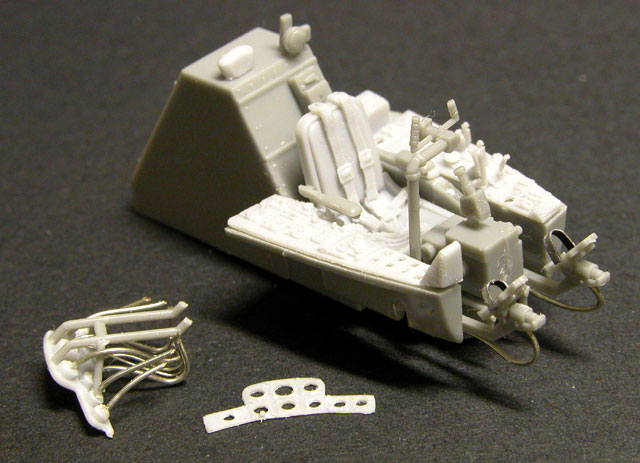

Holes were drilled for instruments as required, and these

parts were then thinned down by gently rubbing them against a medium grit

sanding stick. I prefer to drill my instrument holes first to avoid

possible later damage to the thinned resin part.

Click the thumbnails below

to view larger images:

|

|

|

|

The main components, separated and prepared for painting

|

|

|

|

The detail will all be clearly visible through the large clear nose of the Ar 234

|

|

|

|

A centreline seam and step have been scraped, sanded and polished off the front of the canopy. A bath in Future Floor Wax completes this little job

|

|

|

|

Wiring has been added to the rear of the instrument panel. In hindsight, I might have gone a little overboard!

|

|

|

One small hole was drilled in the back of each instrument

housing with a pin vise. Fusewire of two different gauges was inserted in

the holes. The instrument panel mount (a kit part) was glued to the back

of the instrument panel then the fusewire was bent to shape with

electrical pliers. The long wire was cut off at a length and height that

would meet with the widthways canopy frame that wraps around the nose.

The kit-supplied armrests were glued to the resin seat. I

eventually repositioned the port-side armrest in the "up" position, as it

looks like it would have otherwise interfered with access to the throttles

and levers on the side console. The tiny levers were added to the throttle

an fuel control quadrants with the aid of tweezers. Spare parts are

supplied in the event that any of your levers take the long, one-way trip

to the carpet.

The kit bombsight, control column, rudder supports and

pedals plus some extra detail including rudder foot straps and plumbing to

the rudder assembly was added to the plastic cockpit tub. The resin parts

were test-fitted with no problems, but not glued in place just yet.

Painting and Weathering

The canopy was masked with Tamiya masking tape, inside and

out. The sub-assemblies including the seat, side consoles and instrument

panel, were then temporarily secured to a piece of cardboard. All these

parts were sprayed flat black.

A coat of dark grey was then sprayed from a single angle.

This meant that a "shadow" of black remained visible from certain angles.

Before going any further, I painted the seat backrest

brown and the harness straps off-white. A wash of thinned black oil paint

was then applied to the cockpit tub, the side consoles, both sides of the

instrument panel and the seat.

After waiting a few hours, the wet excess oil wash was

swabbed off, and a coat of Polly Scale acrylic Flat was sprayed overall.

Details such as lever knobs, instrument surrounds and harness buckles were

picked out with a fine brush.

Finally, the acetate instruments were wedged between the

panels, glued into place and the seat was secured in the cockpit tub.

Click the thumbnails below

to view larger images:

|

|

|

|

Canopy halves are masked on both sides in preparation for spraying the interior colour

|

|

|

|

The base coat has been applied and the black oil wash is still wet on the parts

|

|

|

|

Almost finished - just a little tidying up still to do

|

|

|

Cutting Edge's 1/48 scale cockpit set for the new Hasegawa

Arado Ar 234 will add plenty of useful detail to this highly visible area

of the model.

I probably spent four hours or so stretched over a single

day to get the cockpit to this stage, and I consider that was a good

investment of my time considering the result.

Highly Recommended.

Thanks to Meteor Productions for the review sample

Cutting Edge Modelworks accessories are

available online from

Meteor Productions website

Hasegawa's

1/48 scale Arado Ar 234 is available online from

Squadron.com Text and Images Copyright by

© Brett T Green

Page Created 19 September, 2002

Last updated 22 July, 2003

Back to HyperScale Main Page

Back to Reviews Page

|

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search