|

F-104G/J

Cockpit

Cutting

Edge

S

u m m a r y

|

| Catalogue Number: |

CEC48250 / 48251 |

| Scale: |

1/48 |

| Contents and Media: |

14 resin parts and 1 acetate

instrument film |

| Price: |

US$15.99 |

| Review Type: |

FirstLook |

| Advantages: |

Excellent detail; Good fit; Option

to use acetate film instruments |

| Disadvantages: |

Oxygen hoses on seat are missing. |

| Recommendation: |

Highly recommended for the new

Hasegawa kits. |

Reviewed by Dave

Williams

HyperScale is proudly sponsored by Meteor

Productions

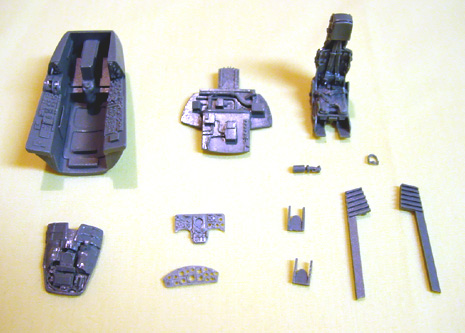

This is one of at least three cockpit sets announced by Cutting Edge for the

new Hasegawa 1/48 scale F-104 kits. This set contains the Lockheed C-2 upward

firing ejection seat as fitted to CF-104s, F-104Js, and many F-104Gs.

Set CEC 48251 is otherwise identical, with the exception that it has the

Martin-Baker GQ7 ejection seat which was used by a few nations, most notably

Germany.

The

set completely replaces the kit cockpit, with the exception of the

throttle handle, for which Hasegawa part R2 is used. The set is molded in

the dark gray resin CE is now using which seems to be fairly strong,

although it is a little difficult to photograph. The

set completely replaces the kit cockpit, with the exception of the

throttle handle, for which Hasegawa part R2 is used. The set is molded in

the dark gray resin CE is now using which seems to be fairly strong,

although it is a little difficult to photograph.

The major item in the set is the well-detailed one-piece cockpit tub.

This part includes the detail of the hatch that forms the cockpit floor.

Although the C-2 seat was upward firing, the seat was installed and

removed from the bottom of the fuselage. I'm not sure why this was, unless

it was a legacy from the early F-104s that had a downward firing ejection

seat. The rear bulkhead is well detailed and the cockpit sidewalls are

separate parts, which are much more accurate than the simple rib detail

molded into the Hasegawa fuselage halves. Once you remove the prominent

molding plug on the front of the cockpit tub, the cockpit parts slip right

in with almost no trimming once the detail molded into kit fuselage is

removed.

Unlike the one-piece Hasegawa instrument panel, the CE panel is molded

in a couple of parts. The side panels are molded with the cockpit tubs and

the upper and lower parts of the instrument panel are separate pieces. The

lower half is attached to the center of the tub, while the upper half is

attached to the detailed cockpit coaming part. This breakdown allows the

installation of the coaming/upper instrument panel after the fuselage

halves have been glued together. Hasegawa implies that you can put their

instrument panel in after the fuselage is together, but as the kit part

has the side panels attached, it is larger than the cockpit opening. |

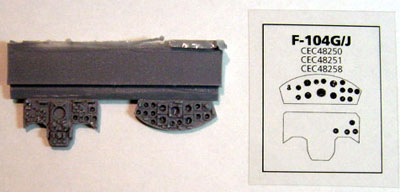

As

cast, the instrument panel has needle detail molded inside all of the round

instruments. As an alternative, CE provides an acetate film panel like what you

get in the Eduard sets. You can sand the backside of the panels until you sand

the back of the instruments out and then apply the film instruments. (The

closeup photo of the instrument panels with the film shows them as they come in

the set. In the photo with all the parts, the instruments have been hollowed

out.) As

cast, the instrument panel has needle detail molded inside all of the round

instruments. As an alternative, CE provides an acetate film panel like what you

get in the Eduard sets. You can sand the backside of the panels until you sand

the back of the instruments out and then apply the film instruments. (The

closeup photo of the instrument panels with the film shows them as they come in

the set. In the photo with all the parts, the instruments have been hollowed

out.)

The Lockheed C-2 ejection seat is a jewel that is designed to slide into the

separate side rails, which are attached to the cockpit floor and top of the rear

bulkhead. To be nit picky, the prominent oxygen hoses that run along the sides

of the seat are missing, although it probably would have been difficult to mold

these as part of the seat as they stand off a little from the actual seat. The

instructions don't mention anything, but Hasegawa parts T2 and T6 represent

these hoses and they might fit, although I haven't tried them yet. As an

alternative, here is a chance to try your favorite 1/48 scale oxygen hose

technique.

The instructions mention that the set can be adapted to the old Monogram kit,

but you are on your own in fitting it. Overall, highly recommended.

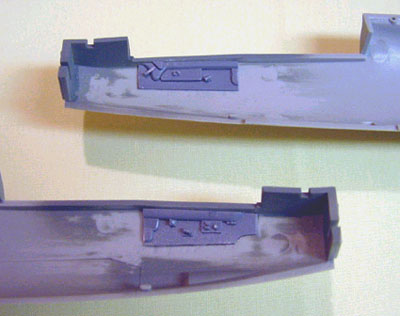

I have already started to fit the set to a Hasegawa F-104J kit. Here are some

of my observations:

-

The

instructions have you dry-fit the cockpit tub, without sidewalls, to the

fuselage halves, use a pencil to mark the location of the sidewalls, and

then remove the tub and glue the sidewalls to the fuselage halves. What

worked for me was to glue, or temporarily tape, the rear bulkhead to the

cockpit tub and then use the open-topped box formed by the tub and rear

bulkhead to adjust the fit of the sidewalls to the tub/bulkhead combination.

The top of the sidewall should line up with the top of the tub at the front

and the top of the bulkhead at the rear. The CE tub is sized to exactly fit

between the bulkhead at the very front of the fuselage halves and the

nosewheel well attached to the underfuselage part, so if you get the

position of the sidewalls off, you may have problems later. The easy way out

is to glue the sidewalls to the tub instead of the fuselage and then put the

whole thing in as one. What I did was to put a small blob of Blu-Tac like

putty on one of the side consoles to hold the sidewall in place, put some

super glue on the back of the sidewall only, and stick the whole assembly

into one of the fuselage halves. Then, I used a paintbrush handle to push

the sidewall against the fuselage side, held it until the glue set and then

removed the tub, leaving the sidewall in place. Repeat for the other

sidewall. The

instructions have you dry-fit the cockpit tub, without sidewalls, to the

fuselage halves, use a pencil to mark the location of the sidewalls, and

then remove the tub and glue the sidewalls to the fuselage halves. What

worked for me was to glue, or temporarily tape, the rear bulkhead to the

cockpit tub and then use the open-topped box formed by the tub and rear

bulkhead to adjust the fit of the sidewalls to the tub/bulkhead combination.

The top of the sidewall should line up with the top of the tub at the front

and the top of the bulkhead at the rear. The CE tub is sized to exactly fit

between the bulkhead at the very front of the fuselage halves and the

nosewheel well attached to the underfuselage part, so if you get the

position of the sidewalls off, you may have problems later. The easy way out

is to glue the sidewalls to the tub instead of the fuselage and then put the

whole thing in as one. What I did was to put a small blob of Blu-Tac like

putty on one of the side consoles to hold the sidewall in place, put some

super glue on the back of the sidewall only, and stick the whole assembly

into one of the fuselage halves. Then, I used a paintbrush handle to push

the sidewall against the fuselage side, held it until the glue set and then

removed the tub, leaving the sidewall in place. Repeat for the other

sidewall.

-

Sanding the backs of the instrument panels to

use the acetate sheet can be a tricky undertaking. There is a fine line

between sanding enough to sand out the backs of the instruments and sanding

almost completely through the panel. You need to ensure your sanding is

uniform, especially on the upper panel as basically the entire panel

contains instruments that get sanded out. Go slow and check your work

constantly. Also, remove the panels from the sprue before sanding. I

recommend getting the backs of the instruments paper thin and translucent

and then punching through with a scalpel blade or small drill bit instead of

trying to remove the back of the instruments by sanding alone. I learned

this lesson the hard way be messing up the first panel I tried.

-

The instructions say to glue the front fuselage

halves together and then insert the completed tub from the bottom. Don't!

The tub is far bigger than either the top or bottom fuselage opening and

needs to go in before the fuselage halves go together.

Dave Williams IPMS/USA 19050

Cutting Edge Modelworks Resin Conversion

Kits and Details Sets are available at Meteor

Productions Website

Review and Image Copyright © 2000 by Dave

Williams

Page Created 26 September, 2000

Last updated 22 July, 2003

Back to HyperScale Main Page

Back to Reviews Page

|

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search